Lupine Publishers | LOJ Medical Sciences

Abstract

The present process

provides an improved process for the preparation of 4-[5-(4-methylphenyl)-3-

(trifluoromethyl)-1Hpyrazol- 1-yl] benzene sulfonamide (Celecoxib) and its

purification and crystallization to produce polymorph. The present process,

which describes the manufacturing process of Celecoxib, which is a non-

steroidal anti-inflammatory drug (NSAID), has the advantage of scaling up to

the industrial level of production. The process uses safe reagents in the

process which makes it for industrial scale operations. The yields in the

process are high, which makes it a cost-effective process. Formation of isomers

are less compared with the all existing process, which makes it effective to

make it to the pharmacopoeia grade. Residual solvents play a very important

role in the impurity profile of APIs as per the ICH Guidelines ICH Q3C (R4). In

this process by carrying out the final step of condensation in the aqueous

medium followed by crystallization, the residual solvents limits are well taken

care of.

Keywords: Non-steroidal anti-inflammatory drug (NSAID); Celecoxib;

Cyclooxygenase 2; X-ray diffraction; Polymorphism; Process

Discussion

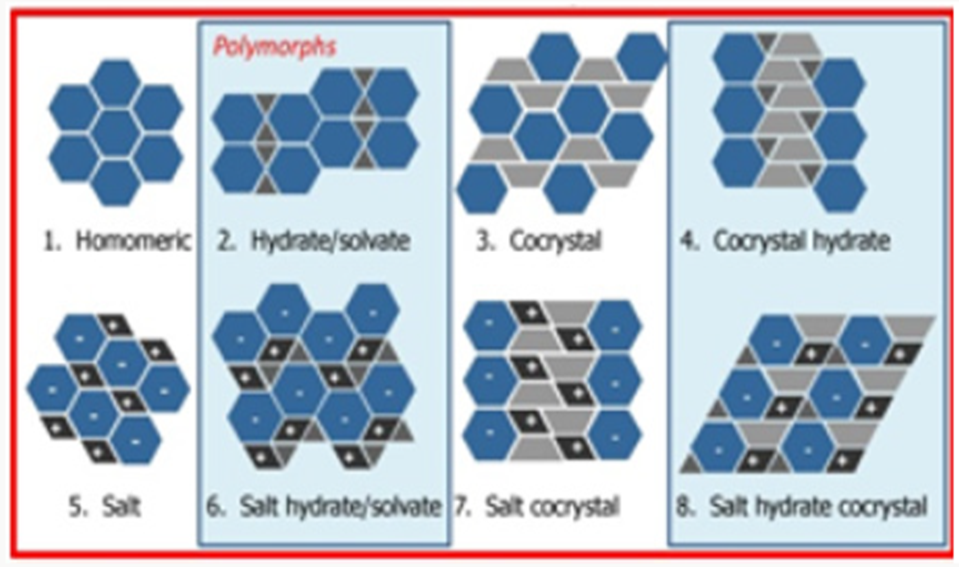

Figure 1: Classes of multi component molecular crystals.

Figure 1 present process

relates to “AN IMPROVED PROCESS FOR THE PREPARATION OF CELECOXIB POLYMORPH

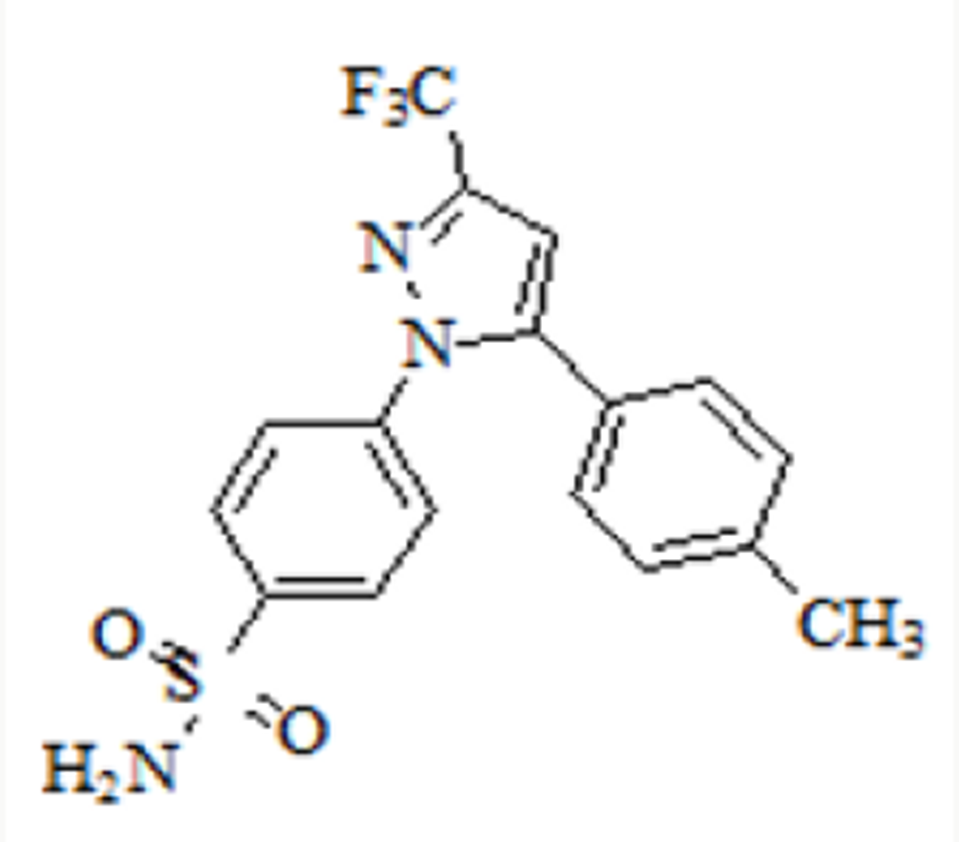

FORM”. Celecoxib is designated chemically as 4-[5-(4-methylphenyl)-3-

(trifluoromethyl)- 1H-pyrazol-1-yl] benzene sulphonamide and is a

diaryl-substituted pyrazole [1]. The compound has the following structure

(Figure 2).

Figure 2: 4-[5-(4-methylphenyl)-3-(trifluoromethyl)-1Hpyrazol- 1-yl] benzene

sulfonamide.

The drug is currently

marketed as Celebrex® in the United States of America by Pharmacia Corporation.

Celecoxib is a non-steroidal anti-inflammatory drug (NSAID) [1] mainly used in

treatment of arthritis, pain, menstrual cramps, and colonic polyps. Celecoxib

blocks the enzyme (cyclooxygenase 2) which makes prostaglandins, resulting in

lowering the concentrations of prostaglandins. As a consequence, reduction in

inflammation and its accompanying pain, fever, swelling and tenderness. The

manufacture of Celecoxib has been described in various patents and to cite a

few references, G. D. Searl & Co. has disclosed method for preparation of

Celecoxib [2-3] in US 5,466,823 which is as under: US 5,134,142 [2], US

5,563,165, US 6,150,534, US 5,892,053, US 2007/0004924, US 2008/0234491, EP

1,528,058, EP 1,167,355, EP 2,246,332, WO 01/42221, WO 03/090730, WO05/014546,

WO 06/051340, WO 08/145733, and WO 2010/095024 have also described the

synthesis of Celecoxib Reddy et al in their publication in Org. Process Res.

Dev., 2009, 13(1), pp 98-101. have disclosed the synthesis (Figure 3).

Figure 3: Manufacture of Celecoxib.

Detailed Description of the Drawings

Figure 1 describes the

powder X-ray diffraction pattern of the Celecoxib Polymorph; Figure 2

illustrates 2θvalues. Figure 3 depicts the DSC thermogram taken at 10:C /min

over a temperature range of 30:C to 200:C for Celecoxib polymorphic form.

Description of the Process

Figure 4: Crystals of Celecoxib polymorph.

The present procedure

describes the preparation of Celecoxib by a novel process and its

crystallization to polymorphic form. The present process for the preparation of

Celecoxib by a process involving condensation of 4,4,4-trifluoro-1-[4-(methyl)

phenyl]- butane-1,3-dione [1] with sulphonamido phenyl hydrazine hydrochloride

[2] in an aqueous medium to give Celecoxib [3]. This is followed by

crystallization from a mixture of solvents [4- 8] containing Aromatic

hydrocarbon and aliphatic ketone. In the condensation reaction the reactants

are added in water and reactions done at ambient temperature. The crude

Celecoxib is isolated by filtration. In the for purification of Celecoxib and

its crystallization to polymorphic FORM Preparing a solution of Crude Celecoxib

in a solvent mixture comprising of an aliphatic ketone (Acetone) and an

aromatic hydrocarbon (Toluene)at reflux temperature followed by cooling

crystallization to give crystals of Celecoxib polymorph [8-12] (Figure 4).

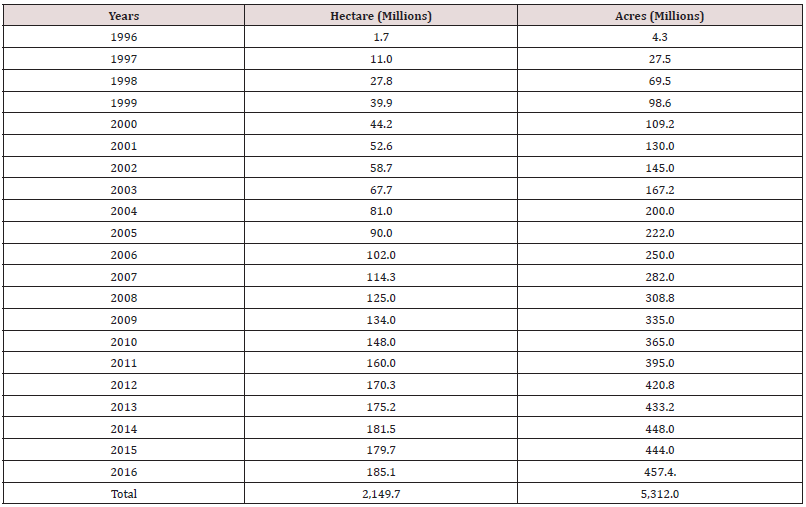

Table 1:

In this process by

carrying out the final step of condensation in the aqueous medium followed by

crystallization, the residual solvents limits are well taken care of. The

yields in the process are higher compared to the prior art, which makes it a

cost-effective process. Formation of isomers are less compared with the prior

art, which makes it effective to make it to the pharmacopoeia grade. Residual

solvents play a very important role in the impurity profile of APIs as per the

ICH Guidelines ICH Q3C (R4). In this process by carrying out the final step of

condensation in the aqueous medium followed by crystallization, the residual

solvents limits are well taken care of [13,14]. The crystallization conditions

are well established to give crystalline polymorph. The powder X-Ray

diffraction pattern of the Celecoxib is given in Figure 1 and 2θ values are

given in Table 1 of Figure 2. The differential scanning calorimeter graph of

the Celecoxib polymorph under specific conditions shows the melting point

around 162.7˚C. The DSC of Celecoxib is given in Figures 3,5, and 6.

Figure 5: Solid Dosage Forms.

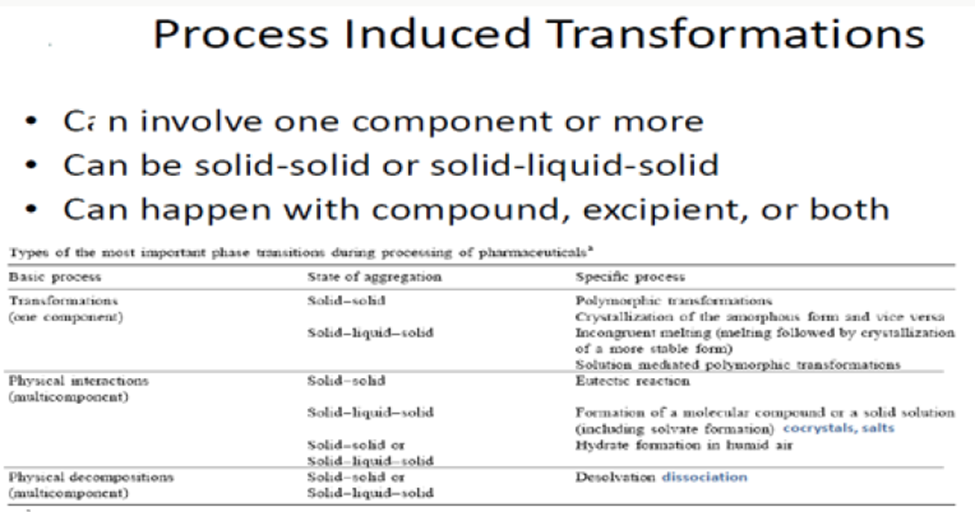

Figure 6: Process induced transformations.

Solid Forms

a) Propensity to produce

different forms not significantly different for salts and non-salts.

b) Need more data on

co-crystals (Figure 7).

The details of the new

methods for preparation of celecoxib are further illustrated in the following

examples.

Example 1: Preparation of Celecoxib

In a 20 liter 3-necked flask, equipped with stirrer, thermometer

and reflux condenser, deionized water (7.9 Liter) is charged and mixture of

4,4,4-trifluoro-1-[4-(methyl) phenyl]-butane-1,3-dione (1.6Kg; 6.95×103mmoles)

and 4-sulphonamido phenyl hydrazine hydrochloride (1.7Kg; 7.57×103mmoles), a resultant

mixture was heated at 75˚C to 80˚C and maintained for 5 hours. The reaction

mixture was cooled to 25˚C to 30˚C to give a slurry. The slurry was filtered

and washed with water (3.2liter) wet- cake was collected and further processed

for purification as given below.

Figure 7: Percentages of forms from Polymorph Screening.

a) Purification and Crystallization to Give Polymorph: Celecoxib wet-cake obtained in the process

described above was taken into 20 liter 3-necked flask, equipped with stirrer,

thermometer and reflux condenser, mixture of acetone (0.54liter) and toluene

(10.8liter) was added and the reaction mixture was heated to 80˚C to 85˚C for

30 minutes. Activated carbon (0.3Kg) was added and the reaction mixture was

further heated to 80˚C to 85˚C. The reaction mixture was cooled to 25˚C -30˚C.

The slurry was filtered, washed with toluene and then dried at 70˚C to yield the

Celecoxib polymorph compound1.35 kg (HPLC purity-99.8% & molar yield;

50.9%).

IR: 3340, 3240, 1600,

1500, 1350, 1280, 1235, 1160, 980, 910, 840, 800,760, 635, 560, 530 cm-1 (KBr pellet)

Proton NMR: Solvent:

DMSO d6, 300 MHz.

Example 2: Preparation of Celecoxib

In a 20liter 3-necked flask, equipped with stirrer, thermometer

and reflux condenser, charge deionized water(9Liter) and mixture of

4,4,4-trifluoro-1-[4-(methyl)phenyl]-butane-1,3-dione(1.6Kg; 6.95×103mmoles)

and 4-sulphonamido phenyl hydrazine hydrochloride(1.7Kg; 7.57×103mmoles), a resultant

mixture was heated at 90˚C to 100˚C and maintained for 5 hours. The reaction

mixture was cooled to 25˚C to 30˚C. The slurry was filtered and washed with

water (3.2liter) wet-cake was collected and further processed for purification

as given below.

Figure 8: Powder X-Ray diffraction pattern of the Celecoxib.

a) Purification and crystallization to give Polymorph: Celecoxib wet-cake obtained in the process

described above was taken into 20liter 3-necked flask, equipped with stirrer,

thermometer and reflux condenser, mixture of acetone (0.54liter) and toluene

(10.8liter) was added and the reaction mixture was heated to 80˚C to 85˚C for

30 minutes. Activated carbon (0.3Kg) was added and the reaction mixture was

further heated to 80˚C to 85˚C. The reaction mixture was cooled to 25˚C -30˚C.

The separated solid was filtered, washed with toluene and then dried at 70˚C to

yield the Celecoxib polymorph compound1.24 kg (HPLC purity-99.3% & molar

yield; 47%) (Figures 8-11c).

Figure 9: 2θ values.

Figure 10: DSC of Celecoxib.

Figure 11c:

Conclusion

The distinct advantage

of the present method of preparation over the prior art can be summarized as

per below:

The present process,

which describes the manufacturing process of Celecoxib, which is a non-

steroidal anti-inflammatory drug (NSAID), has the advantage of scaling up to

the industrial level of production. The process uses safe reagents in the

process which makes it for industrial scale operations. The present process

provides an improved process for the preparation of 4-[5-(4-methylphenyl)-3-

(trifluoromethyl)-1H-pyrazol-1- yl] benzene sulfonamide (Celecoxib) and its

purification and crystallization to produce polymorph. The yields in the

process are high compared to existing process which makes it a cost-effective

process. Formation of isomers are less compared with the prior art, which makes

it effective to make it to the pharmacopoeia grade. In this process by carrying

out the final step of condensation in the aqueous medium followed by

crystallization, the residual solvents limits are well taken care of. The

yields in the process are higher compared to the prior art, which makes it a

cost-effective process. Residual solvents play a very important role in the

impurity profile of APIs as per the ICH Guidelines ICH Q3C (R4)